WITH pressure mounting globally on farmers and growers to reduce their use of chemicals, alternative methods of keeping crops free from pests are becoming more popular. Environmentally-friendly methods of pest control, such as using predatory mites in greenhouses, can be an effective biological alternative to chemical use.

Increased use of pesticides, coupled with a warmer climate, is also hurting numbers of bumblebees, an essential natural pollinator of fruit and vegetables. In response to this, a company in Spain’s Almeria region is trying to counteract the decline in bumblebees by breeding their own to export to growers all over the world.

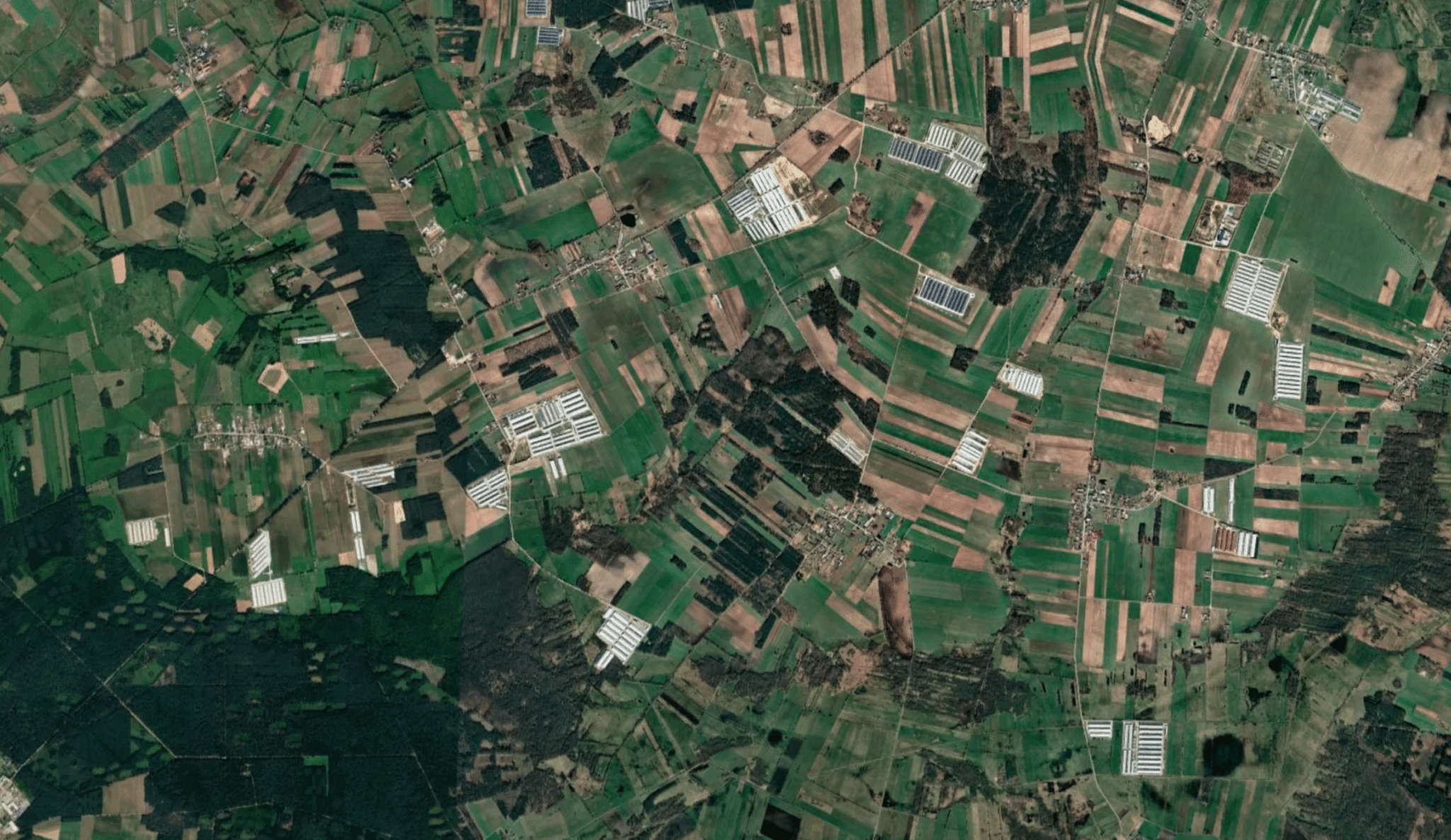

The Almeria region is the one of the powerhouses when it comes to producing fruit and vegetables to be exported mostly into Europe; a business worth millions of euros per year. As well as bumblebees, Agrobio is producing millions of mites per month to export to growers as a cleaner method of keeping their produce free from pests.

It was the pioneer in the production of bumblebee hives in Spain, which totally revolutionised the pollination of tomatoes in greenhouses there. Agrobio was founded in 1995 by the nursery company Almeriplant and the Dutch company Bunting Brinkman Bees. Today, it exports bees and insects to over 40 countries in the world and has subsidiaries in Turkey, Denmark, Morocco and France.

Agrobio carries out the entire production of bees in its own factory, recreating the bumblebee’s life cycle in strict controlled seasonal environments. The production system is a closed circle, with all queens beginning the cycle selected according to the highest health and quality standards.

Isabel Mendizabal, Agrobio business coordinator, said: “We produce over 700,000 hives per year and export to more than 40 countries. Today bumblebee numbers are suffering a lot with climate change, but they are very important agents to pollinate crops. It is vital we produce bees to keep numbers high.”

Agrobio uses only natural nutrients to feed the bees, including pollen, used to build the hive and get the proteins they need to grow; and nectar, which contains the sugar they use as source of energy. Every stage of the production process falls under strict quality control measures, to ensure the bees are in optimal conditions. Expert veterinarians select the best queens and hives at each stage of production.

Bees are exported all year round in hives with 100 bees plus inside, which are ready to pollinate the crops immediately. Each hive includes a fertilised queen, adult workers, worker pupae, larvae, eggs and enough food to meet the life cycle of the bees.

Isabel added: “Using bumblebees as biopollinators and beneficial insects for biological control of pests we avoid the excessive use of phytosanitary substances. As a result we restore the natural balance, and we create healthier, safer and more sustainable working environments which provides clean, safe and healthy fruits and vegetables.”

The bumblebees are particularly good pollinators for fruits such as cherry, nectarine, apricot, plum, kiwi, apple and pear. They are also useful for almond trees, watermelon, melon, strawberry, raspberry, blueberry and blackberry plants. The Agrobio hives can be placed inside greenhouses and in the open fields as the nest is protected from moisture, snow and rain. Using tomatoes crops as an example, around 25 hives of bumblebees would be required under normal conditions, to pollinate one hectare.

Agribio’s mites production

In the Almeria region, prior to 2006, fruit growers were using excessive volumes of chemicals on their produce, simply because some of the pests were becoming immune to them. The co-ops managing the sales of the crops were finding high levels of chemical residues on the fruit, and this started to affect sales as customers were refusing their orders.

To increase food safety, and to boost sales, the region implemented new practices to start using biological controls of pests such as predatory mites. At that time around only 15 per cent of growers in the Almeria region practised biological control but that number has grown to around 80 per cent today. Agrobio has set itself targets to be one of the leading producers and suppliers of predatory mites to growers as a biological control for pests.

The production cycles of these mites is very fast as the mites multiply in a week to 10 days, allowing the company to scale up its production quite quickly. Maria del Mar Morales is in charge of mites production at Agrobio. She said: “The production of mites at Agrobio started back in 2006 due to the implementation of biological control in southeastern Spain to provide an immediate response to growers against pests such as whiteflies and thrips, motivated by the prohibition of active ingredients for these pests.

Jose Ruiz farms around 7,000 square metres in the Berja municipality of Almeria, a region famous for growing a variety of export crops. He predominantly grows sweet peppers and stopped using chemical pest control 16 years ago in favour of biological methods. “Before we switched, we were finding some pests, like thrips or aphids, were more difficult to control using phytosanitary treatments. The biological control strategies, based on a preventive establishment of insects, protect crops from pests without generating any resistance. Moreover, we obtain high quality products in a healthier working environment, which are exactly what the market requires,” he said.

When producing the mites, Agrobio recreates the natural cycle of the mites by generating an optimal environment of temperature and humidity along with specific diets specially prepared for their development. Maria added: “Thanks to the large scale production of mites, this allows us to make massive releases that are also profitable for the grower. Together with the formulation and supply of the mites in sachets, which make the work of small biofactories, we get a longer duration in the crop allowing preventive releases and anticipate the pest having a bioprotected plant from the beginning.”

Thought it might interest everyone that in the early 1970’s, I had a job at Bio-Control in the high Sierra Nevada Mountains of California. Ladybug collectors would bring us heaving gunnysacks of ladybugs (they hibernate in enormous clusters). Bio-Control then filtered the bugs from the branches through sieves placed over horse troughs. Then we’d scoop them with different sizes coffee cans. The half-pints, pints, and gallons were placed in cold storage, reinstating hibernation. When orders came in from gardeners, we’d ship the requested amount to homes!

We also provided Praying Mantis sacs.

A crazy time from my past.

Interesting article. I just can’t help but feel that the narrative remains the same – profit over people, plants and soil health. Instead of creating natural habitats for pollinators and preditors locally by sowing a rich mix of flowering plants as well as having some trees and shrubs on the land, to create biodiversity on farms and encourage a healthy ecosystem, business is taking priority. No doubt these mites and bees are patented and although may be seen as a better alternative in the short-term to chemical control measures, it creates the same dependency for farmers. Plus, we don’t know what problems these creatures will create in the future either. We just go around in circles, instead of thinking about viable long-term solutions.

Agree 100% RobJMatthews